Aquaculture is rapidly evolving, there’s no escaping it and now advances in technology and best practice make land-based intensive fish farming a viable option for our food supply needs. It has long been known that rearing fish at sea has challenges that have now become unsustainable. Apart from commercial viability, increasing scrutiny is given to our environment and therefore maintaining control of a more sustainable and balanced system is increasingly deemed to represent the way forward for our industry.

Rearing fish on land brings control back to the farmer, we are now able to optimise the living conditions for brood-stock whilst at the same time preventing escapees and the known damage they inflict on local, wild populations. Where very difficult to manage in the past, biosecurity can be maintained and pollution is now more manageable.

Environmental, social and governance (ESG) factors are becoming increasingly important to all stakeholders and taking a more sustainable approach to rearing fish, whilst requiring investment, is now paramount and coming at a time where Global inflation and energy costs are rising, this is something that all operators are under continuing pressure to try and mitigate.

Fines continue to be a problem

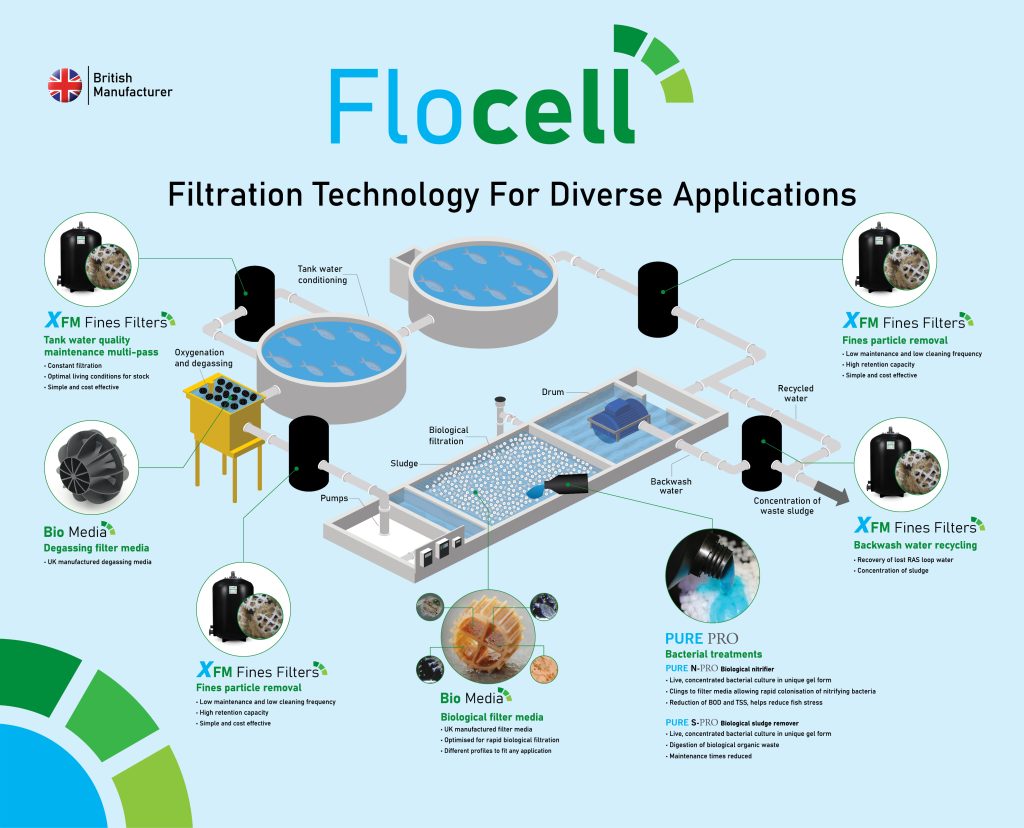

One of the significant hurdles the industry has faced since RAS became popular, is the management of fine particle removal. Fish produce waste that needs to be managed but biological filtration by way of Moving Bed Bio-Reactors (MBBRs) produces particles as bacterial communities used in nitrification are replaced by new organisms. Fixed Bed Bio Reactors are used by some but some of these run into significant design issues surrounding cleaning, aeration and associated sludge removal which leads to anoxic conditions within the bed, poor nitrification and critical danger of H2S.

The multitude of pumps managing inline systems results in a continuing degradation of larger particles to smaller ones which then become increasingly complex to manage and reduce. Flocell XFM filters and media have been designed to effectively control this problem and are highly flexible as to their deployment.

A unique solution for aquaculture

XFM filters are currently the only solution that provides effective filtration with no hydraulic head loss. As they can be used under gravity, the cost savings on a power alone basis is substantial. Moreover, XFM filters have in excess of 100 times the retention capacity of similar sized sand filters meaning that less interaction is needed, increasing profitability and reducing downtime.

At a time when sustainability is now paramount and low-carbon solutions are always being sought where possible; XFM filters will deliver exceptional performance whilst lowering the carbon balance.

Exceptional performance with even the heaviest of solids load

XFM filters use a high-performance proprietary media element that has been specifically designed to capture fine particles and retain them within the structure until cleaning. This means that whilst suffering no head loss, a huge solids load (over 200mg/l)can be easily accommodated with no loss of performance. A single XFM unit can retain over 100kgs of solids and still filter at optimal efficiency, this means that they can be operated for extended periods with no requirement for cleaning.

Very low water loss

Typical sand filters require significant volumes of water to effectively clean themselves. XFM units are cleaned by air sparging for a short cycle and therefore only a small volume of water is sent to waste unlike other technologies where multiple volumes of water are lost, and far more frequently.

Exceptional retention capacity

XFM Media can be used in large installations with high flow rates to capture particles down to 20um with 100 percent efficiency (at 10um the media is 80 percent efficient). Solids management is undertaken on a periodic basis by vigorously aerating the basin before sending the concentrated waste to final settlement or treatment nearby.

XFM Filters are also highly effective when continuously filtering a body of water and in situations where they can be deployed on individual fish tanks on a permanent loop, they can be used to keep particles present at an absolute minimum, requiring very infrequent cleaning and taking the pressure off other systems downstream. Hatcheries Keeping water in optimal condition is vital in ensuring lower mortalities and better fish health. XFM filters are used to both effectively manage particles within the RAS loop or feed-water sump. A single low-cost filter can comfortably manage flows of 20m3/hr and where constant filtration is required, units can be placed in series and cleaned independently when needed.

These filters can be simply specified with manual valves or automated for completely independent operation.