Home / FAQs

FLOCELL

Frequently Asked Questions

Can't find your answer from the list below?

Flocell XFM modular filtration systems are a series of self-contained immediately-deployable filtration units housed in Winterised weatherproof converted shipping containers which have been designed to manage flow rates of between 5 lps (20m3/hr) and 40 lps (160m3/hr).

All they require is a feed and outlet connections to operate.

The open cell media used in our Flocell filters work by settlement not entrapment (like sand or glass). Each cell is in essence a mini lamella separator.

Any debris entering the filter bed will lose kinetic energy as it passes through the filter pack until it settles out in or on one of the elements.

As there is 80% free area in a piece of Flocell media compared with sand’s 5%, the Flocell media can hold significantly more debris before backwashing is required.

Its large free area results in less resistance to water, which means a greater flow with negligible head loss can be obtained.

Click here to watch our video.

The only things required to bring an XFM Modular Filter online is flat ground of the dimensions of the unit being deployed, a power feed and connections of feed water to and away from the unit.

Traditional filters using barrier technology require powerful pumps to operate due to the inherent difficulty in forcing water through a particulate barrier filter.

Open cell media employed in XFM filters uses the lamella principle to settle fine particles out by gravity throughout the whole filter depth.

As no surface blocking occurs, no pressure builds on the supply side of the filter meaning that with adequate operational head, XFM filters can operate under gravity if required.

The open cell media used in our Flocell filters work by settlement not entrapment (like sand or glass). Each cell is in essence a mini lamella separator.

Any debris entering the filter bed will lose kinetic energy as it passes through the filter pack until it settles out in or on one of the elements.

As there is 80% free area in a piece of Flocell media compared with sand’s 5%, the Flocell media can hold significantly more debris before backwashing is required.

Its large free area results in less resistance to water, which means a greater flow with negligible head loss can be obtained. Flocell XFM Fines Filters provide a constant flow rate, at a constant pressure, so turnover times and the circulation of water is always maintained.

Any equipment which requires a constant flow will never stop working on “no flow”. The filtration quality is also maintained, unlike sand or glass which varies according to how blocked the media is.

Flocell media is also 87.5% lighter than sand making it easy to handle and reduced transport costs and associated carbon balance. The open nature of Flocell media ensures the filter bed will be oxygenated (if necessary) by influent water there are never any unwanted anaerobic conditions or channelling issues within the filter pack.

As air is used for cleaning, no large volumes of backwash water are created and no backwash tanks needed.

Yes, Flocell media are not subject to degradation by ozone.

Yes, no additional water is used in the cleaning process and therefore only very small volumes are returned to process as carryover is cleared immediately after cleaning.

Flocell media can hold more debris than traditional media before a backwash is required, so the frequency of backwashing can be reduced. The amount of water required to clean Flocell media is only the volume of the filter itself.

Flocell fines filters will require less backwashing than traditional media, however each installation is different.

We typically find that the increased retention capacity means that a filter cleaned daily can be left for a number of weeks before needing cleaning.

Under typical operating conditions cleaning would be typically weekly. Inorganic systems are often extended to 2-weekly.

In gravity systems, OPEX costs are limited to power used to operate the included AirClean system for approximately 10 minutes per week.

In pumped systems, the OPEX cost is the pump supplying the XFM unit and the AirClean blower. There are no consumables needed.

There are no mechanical parts in the XFM Modular Filter itself.

Moving parts are limited to the air blower which is a 365x24x7 rated unit; therefore it’s service life is significantly extended by its 0.1% usage rate.

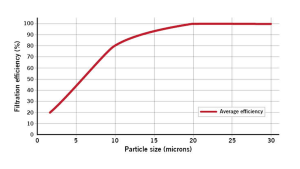

We do not publish absolute performance information as every system installed is operated differently.

IFTS have independently validated the particle size efficiency but absolute performance is a function of loading rates, particle size distribution and flow rates.

Flocell can undertake Particle Size Analysis for customers at very competitive rates if required.

Click here for more information on our Flocell Mobile Lab service.