Home / Integration

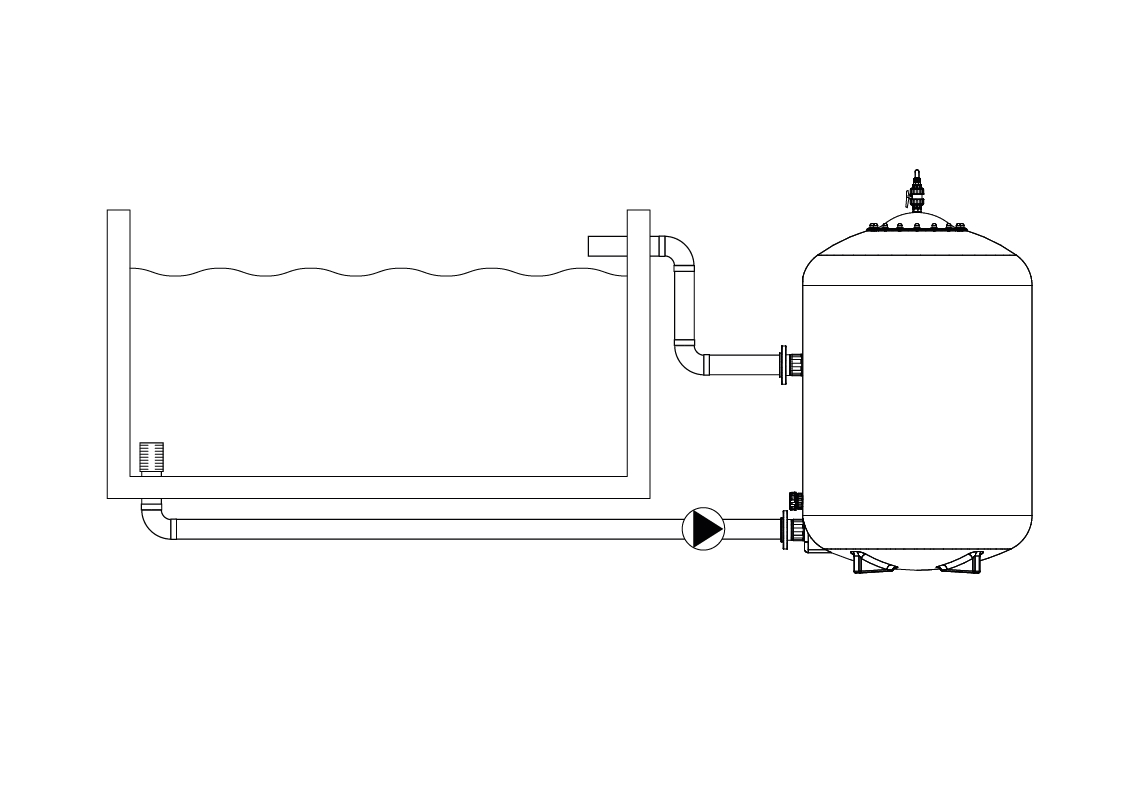

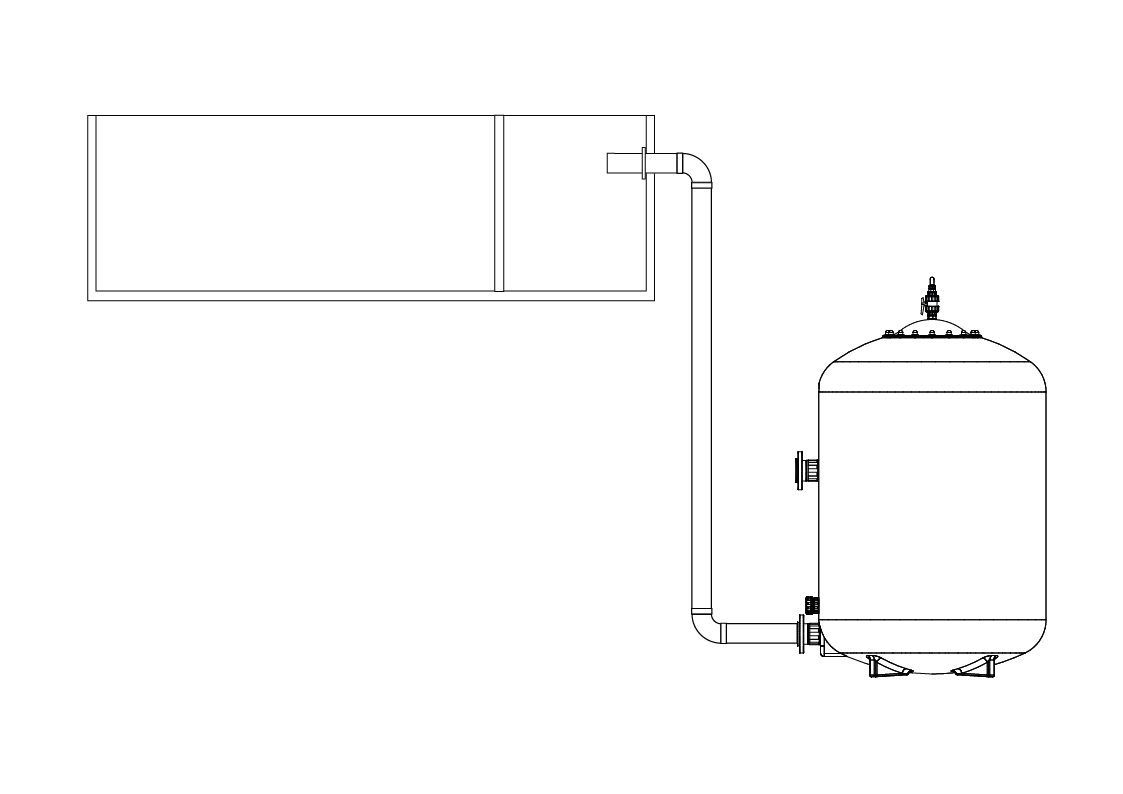

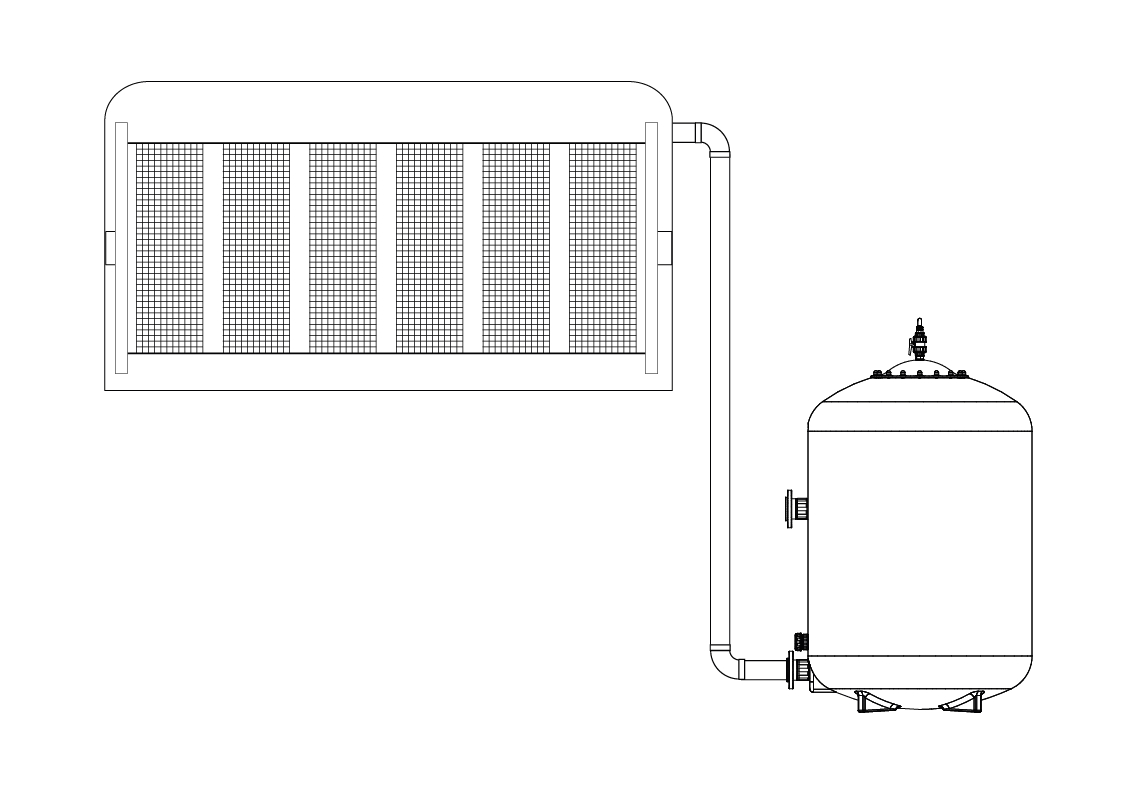

Gravity or pump-fed, containerised XFM packaged solutions can be commissioned within one hour and require no civil engineering. Typical cleaning cycles of only 30 minutes reduce site visits, labour and costs. No moving parts eliminate the need for short-term consumables and require minimal periodic servicing.

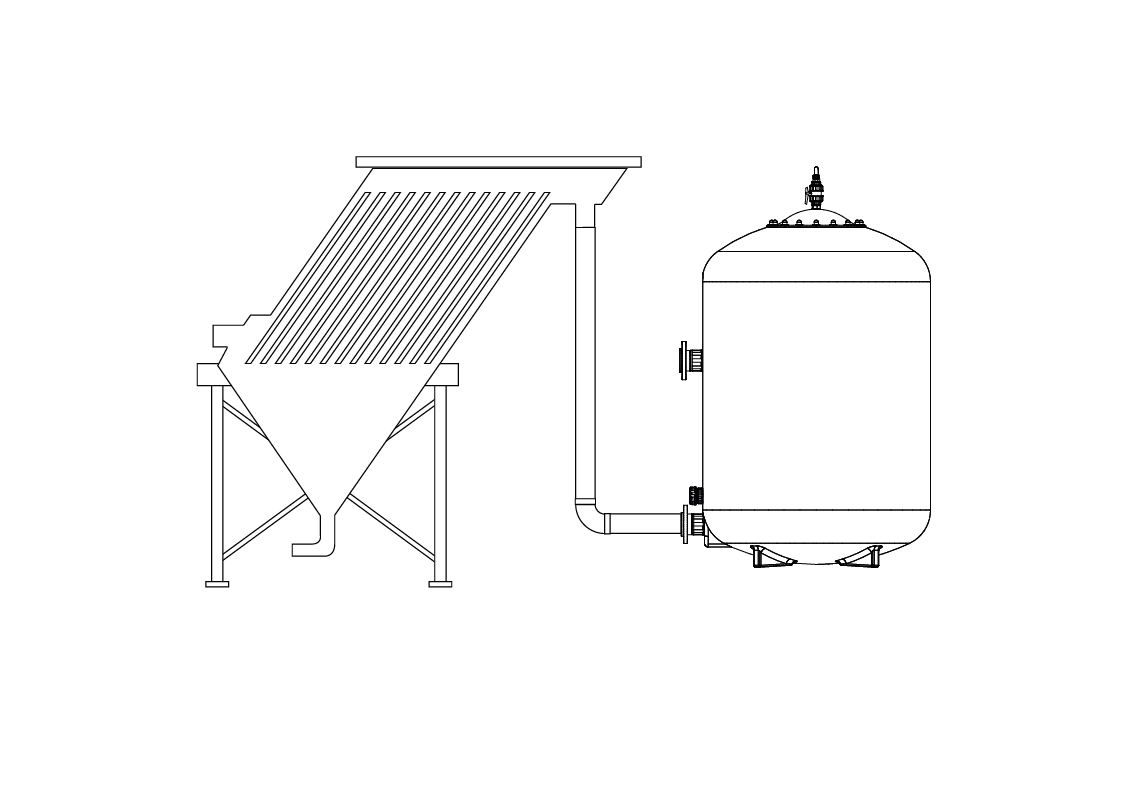

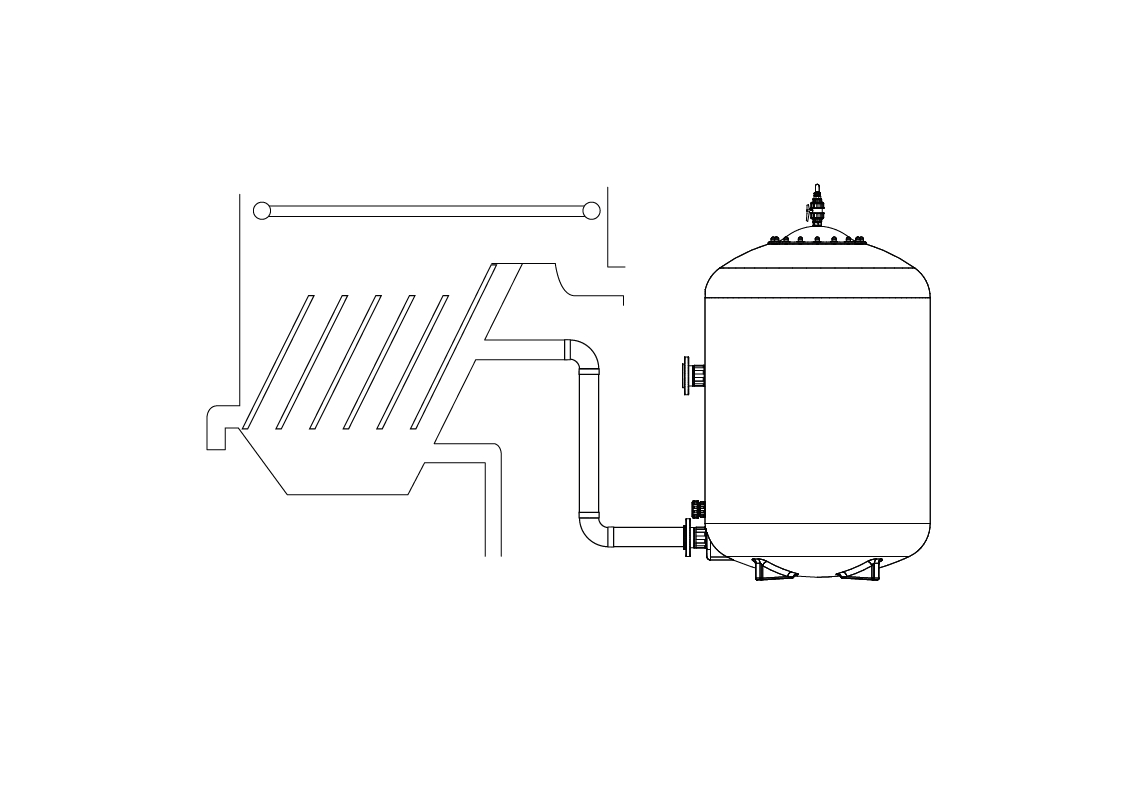

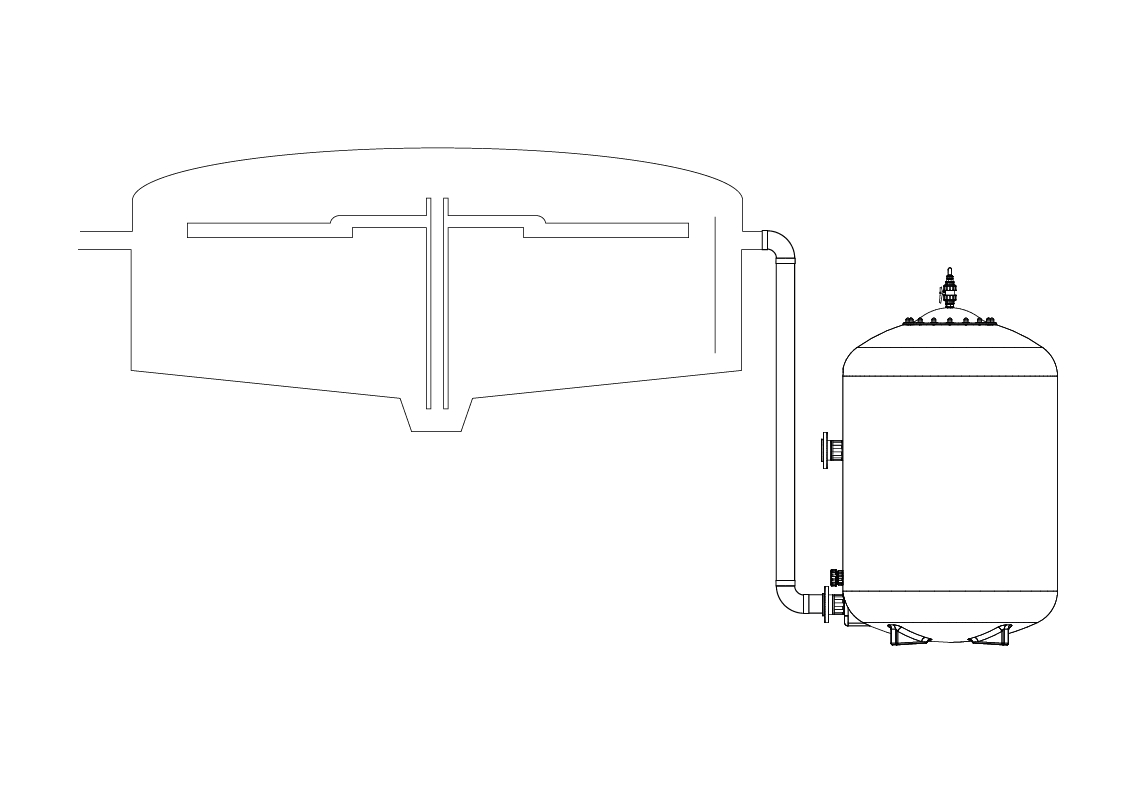

Flocell XFM Fines Filters have been designed to be modular and conform with any flow rate required, making them suitable for a variety of applications.

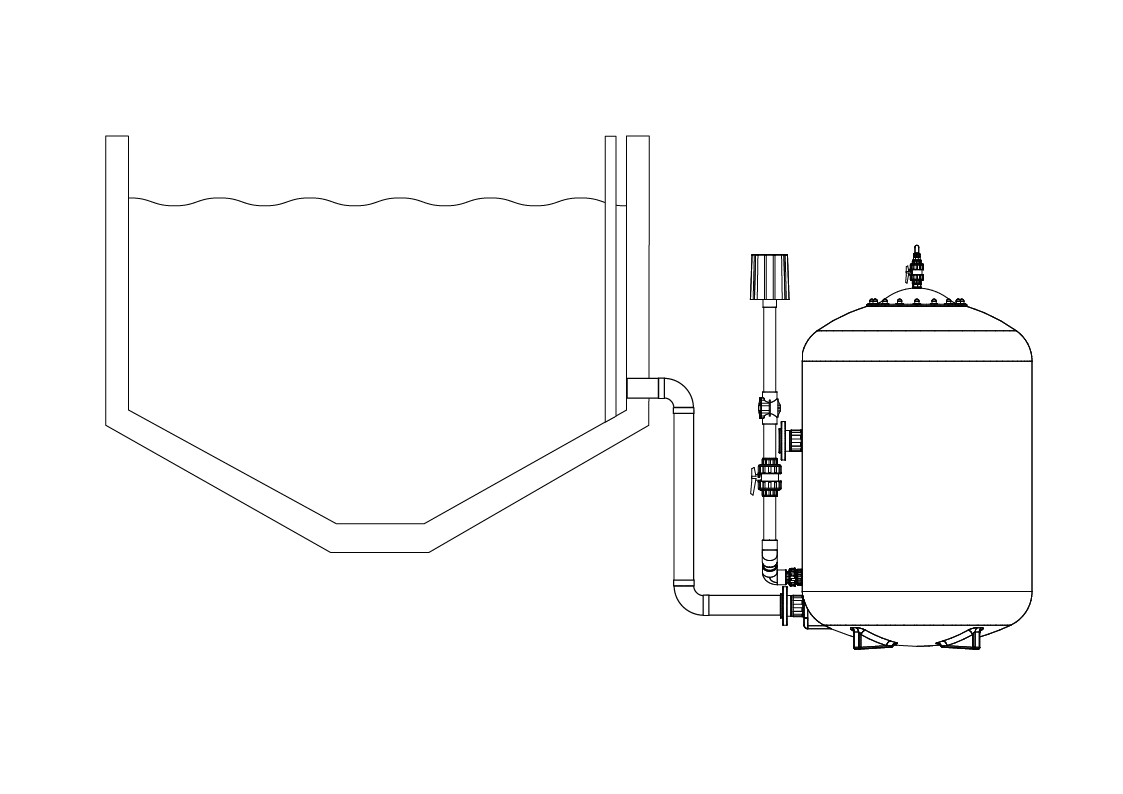

When used to constantly filter a body of water, XFM Fines Filters can be operated at higher flows to maintain optimal water quality.

Can be used either before or after RBCs to enhance performance as well as being used to receive backwash water.

Discover the versatile applications of Flocell XFM Filters in Aquaculture Tank Maintenance.

Flocell provides sustainable filtration solutions for aquaculture, wastewater and other industrial applications.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |